The tube end forming machine is widely used in aerospace, industrial, furniture, and automotive industries for tube end expansion, reduction, and forming. It features hydraulic control for both forming and clamping, and the microcomputer controller supports multiple languages, English and Chinese.

| Standard Configuration | TM-100 |

| Number of Stations | Single Station |

| Max Forming Capacity | Φ100 × 2.5 mm |

| Forming Length | 210 mm |

| Pressure | 14 Mpa |

| Forming Speed | 160 mm / 6 seconds |

| Work Indicator Light | YES |

| Processing Materials | Carbon steel, stainless steel, copper, aluminum, and other metal pipes |

| Certification | ISO9001 |

● Capacity 30mm O.D. tube

● Adopt the PLC control system, touch screen, easy to operate.

● Adopt a Mitsubishi servo motor to control tools shifting accurately and stably, the precision is as high as ± 0.01, accurate and stable.

● Servo motor control die change, ball screw and high-precision linear guide rail are used for propulsion, stable and smooth

● High-performance imported hydraulic valve elements are used for mold change. Simple tool change and setting

● Equipped with a hydraulic cooling system to ensure long-term stable operation under high temperature

● Mobile foot switch has two functions of start and emergency stop

Adopt Mitsubishi servo motor to control the tool to move accurately and stably, the precision is as high as ±0.01, accurate and stable.

Equipped with hydraulic cooling system to ensure long-term stable operation under high temperature.

The tube end forming machine produces high-precision tube ends with various shapes such as flaring, reducing, beading, and sealing grooves. The finished products are burr-free, crack-free, and ready for direct use in welding, sealing, or assembly applications.

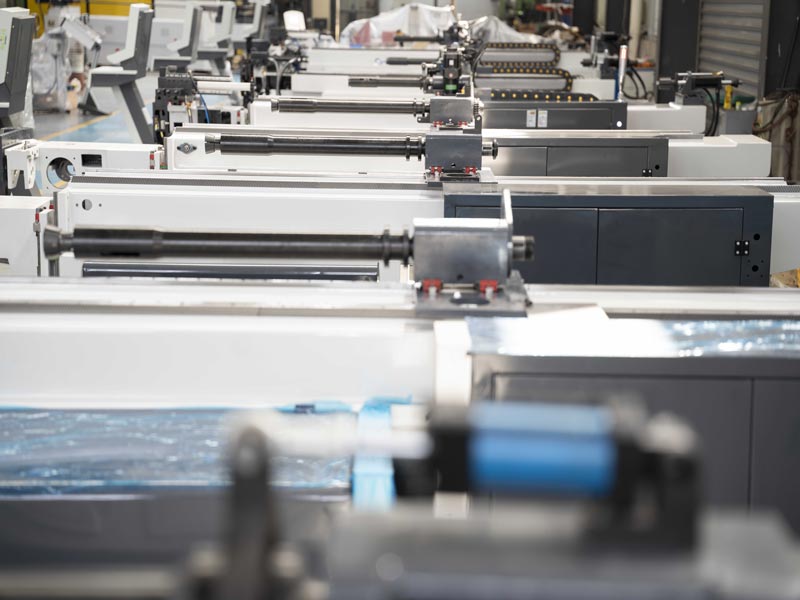

Welcome to our production workshop, which is equipped with advanced CNC machining equipment, fully automatic welding line and efficient assembly line to fully guarantee the precision and quality of each pipe bender. Standardised production processes, clean and orderly working environment and strict quality inspection system is the solid backing for the stability and reliability of our products. Through the real scene display, let you feel our manufacturing strength and professional attitude.