This left-right CNC pipe bending machine features bidirectional bending capability, enabling both left and right bends in a single setup for complex 3D pipe shapes. It offers high precision and efficiency, ideal for automotive, HVAC, aerospace, and other industries requiring intricate multi-angle pipe processing.

| Parameters | L&R CNC Pipe Bending Machine |

| Control system | PLC control |

| Max bending capability (mild steel) | Φ15×2 mm |

| Bending radius | 1.5D-2.0D or customized |

| Bending angle | -190°~190° |

| Max effective mandrel length | 1200mm |

| Bending speed | 280°/sec(can be adjusted) |

| Bending accuracy | ±0.1° |

| Bending servo motor power | 2000W |

| Feeding speed | 900mm/sec(can be adjusted) |

| Feeding accuracy | ±0.1mm |

| Feeding servo motor power | 1000w |

| Rotating speed | 720°/sec(can be adjusted) |

| Rotating accuracy | ±0.1° |

| Rotating servo motor power | 200w |

| Mold shifting speed | 180mm/sec |

| Mold shifting accuracy | ±0.1 mm |

| Mold shifting servo motor power | 750W |

| System hydraulic pressure | 4MPa |

| Machine size | 2400×750×1300mm |

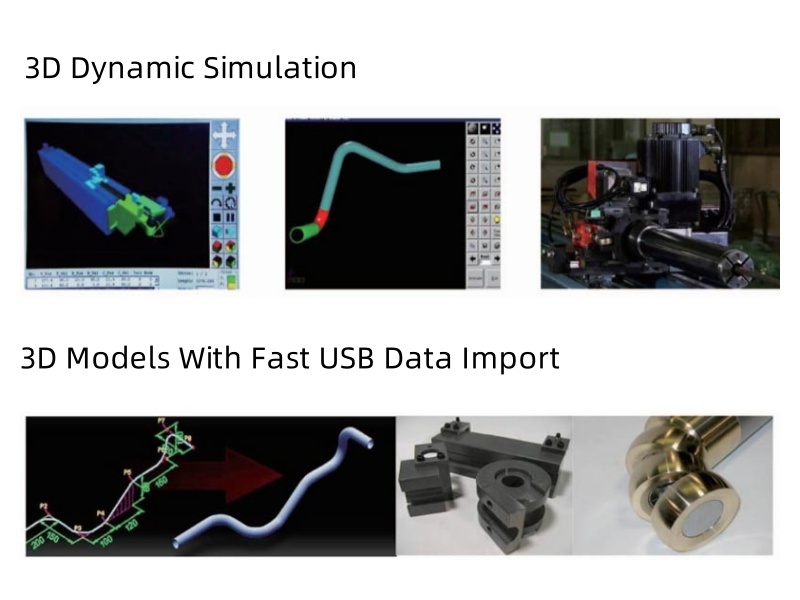

In the industrial control system, it supports three-dimensional dynamic simulation, which realistically reproduces the operating state and action process of the equipment. At the same time, it can quickly import 3D graphics and related data via USB, which is easy to operate and improves the modeling and debugging efficiency, and helps intelligent manufacturing and precise control.

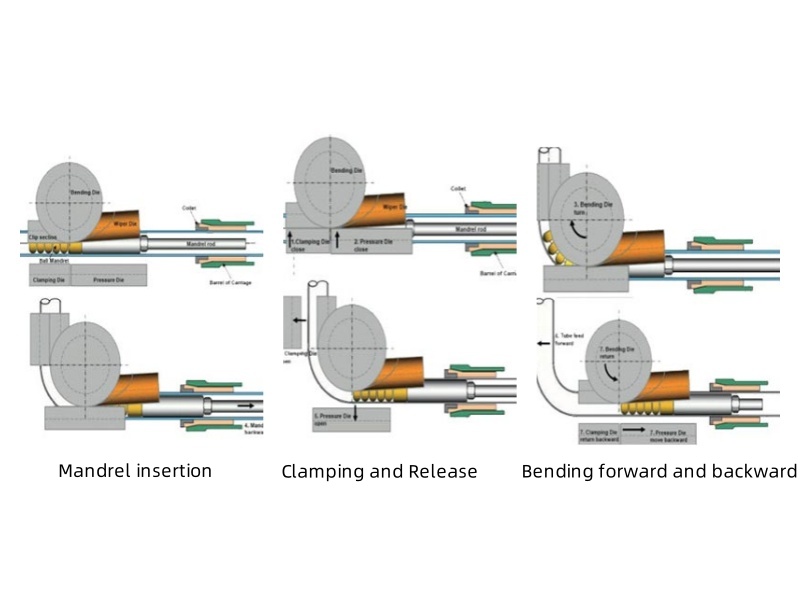

During operation, the mandrel is precisely inserted to support the pipe internally, followed by quick clamping to ensure stable positioning. The bending arm performs forward or backward bending as programmed, meeting multi-directional forming needs. After bending, the clamp releases automatically, enabling efficient, precise, and continuous high-quality pipe bending.

We use only world-renowned quality components in the production of our bending machines: Japan Mitsubishi servo, Germany Rexroth hydraulic pressure, France Schneider Electric, Japan NOK seals, Siemens or Japan Mitsubishi numerical control system.

● The servo motor and drive system are made by Panasonic brand from Japan and comply with IEC 60034 electrical standard.

● Provides high precision and stability motion control, capable of precisely adjusting the bending angle and position.

● With fast response speed and low noise, the drive system is also equipped with energy efficiency optimisation function to improve productivity.

Our CNC pipe bender is suitable for a wide range of specifications and materials of tubes, can achieve different radii, angles and complex shapes of high-precision bending, whether it is round, square, shaped tube, or stainless steel, carbon steel, aluminium alloy and other materials, can easily cope with, widely to meet the diversified processing needs of automotive, furniture, aerospace, fitness equipment and other industries.

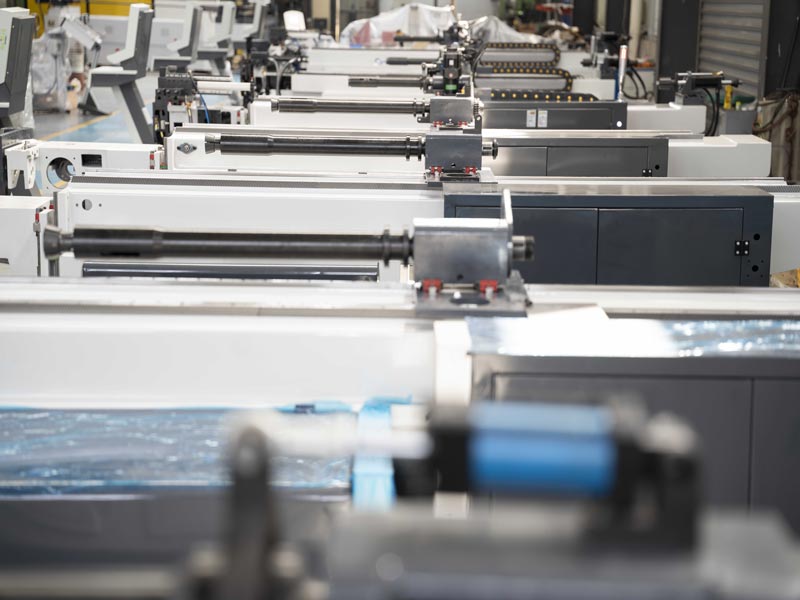

Welcome to our production workshop, which is equipped with advanced CNC machining equipment, fully automatic welding line and efficient assembly line to fully guarantee the precision and quality of each pipe bender. Standardised production processes, clean and orderly working environment and strict quality inspection system is the solid backing for the stability and reliability of our products. Through the real scene display, let you feel our manufacturing strength and professional attitude.