This fully automated tube bending machine features servo-controlled bending, rotation, and feeding, with hydraulic clamping and core pulling. It includes a PLC system (optional Windows XP), customizable cooling options, and an automatic lubrication system for smooth operation.

| Standard Configuration | SB-63CNC |

| Control System | CNC full digital control |

| Mold Layers | Single Layer Mold |

| Servo System | E Servo bending H Hydraulic Pipe Bending |

| Bending Capacity | Φ63×2 mm |

| Mandrel Extraction Length | 3000 mm |

| Bending Speed | 40 °/s |

| Feeding Speed | 800 mm/s |

| Rotating Speed | 170°/s |

| Bending Accuracy | ±0.1° |

| Feeding Accuracy | ±0.05 mm |

| Rotating Accuracy | ±0.05° |

| Max Bending Angle | 190° |

| Input Values | Y, B, C or X, Y, Z |

| Lubrication System | Automatic lubrication system |

| Processing Materials | Carbon steel, stainless steel, copper, aluminum, and other metal pipes |

| Certification | ISO9001 |

● Automatic feeding according to the set programme to ensure stable delivery of tubes.

● Automatic adjustment of tube feeding speed with CNC system for precise control.

● Improve the production efficiency and reduce the instability of manual operation.

We use only world-renowned quality components in the production of our bending machines: Japan Mitsubishi servo, Germany Rexroth hydraulic pressure, France Schneider Electric, Japan NOK seals, Siemens or Japan Mitsubishi numerical control system.

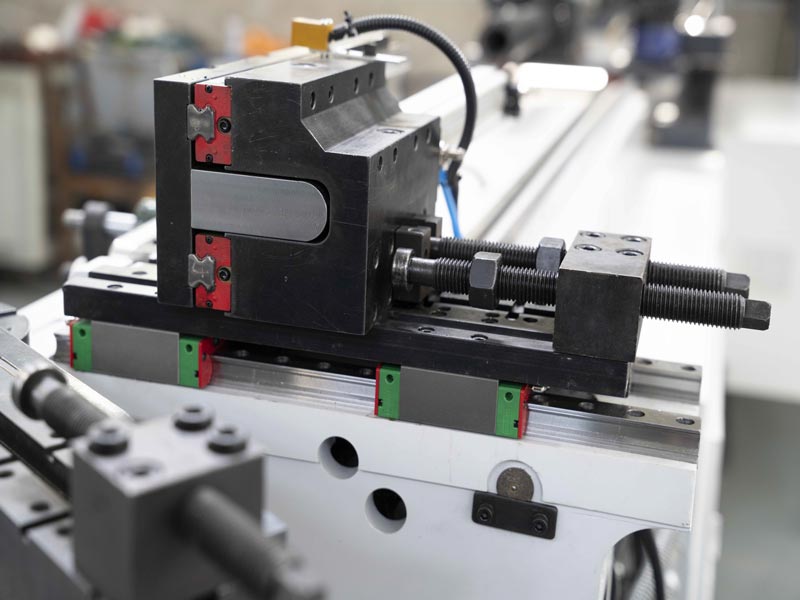

● Made of wear-resistant materials for high durability.

● Can be changed quickly according to the pipe specification to ensure bending precision.

● Suitable for all kinds of pipe bending to ensure good bending effect.

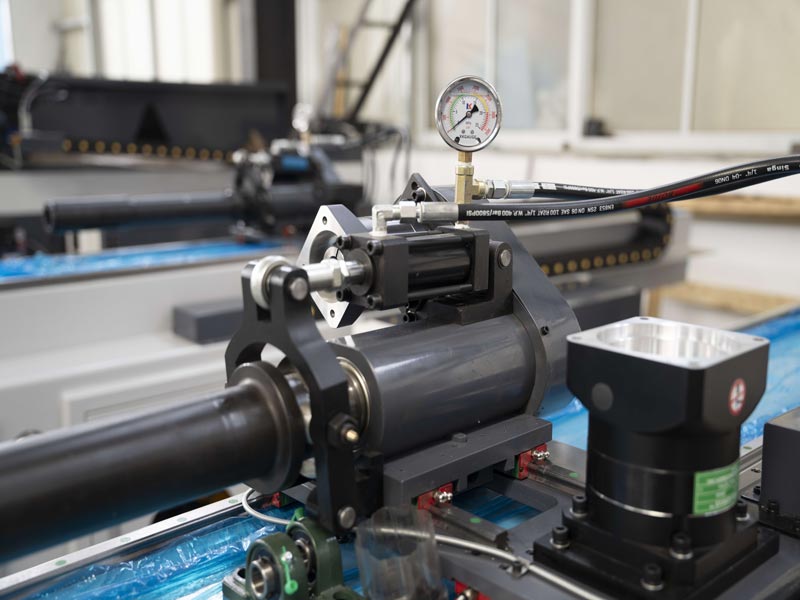

● Supplied with fully automatic hydraulic drive for driving the main moving parts of the pipe bender.

● Equipped with high efficiency hydraulic pump and pressure regulator for precise pressure control.

● Ensures stability and consistency in the pipe bending process.

The CNC bender's hydraulic system, metal surfaces, motors, bending dies and welded connection parts are all coated with a rust-proof film before shipment to prevent moisture and oxygen from leading to corrosion or rust and to ensure that the equipment stays in good condition during shipment.

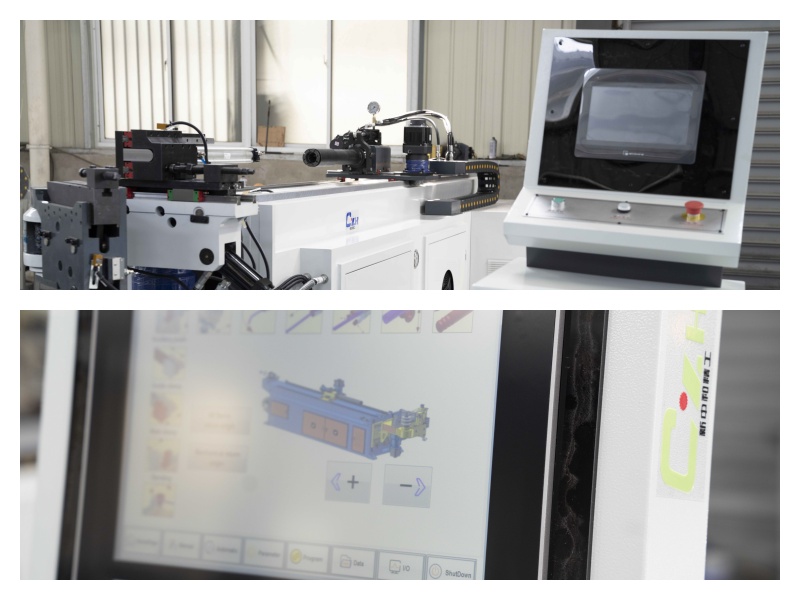

● Equipped with a high-resolution touch screen display, in line with ISO 9241 ergonomics standards, the interface is simple and intuitive, easy to operate.

● The operation interface is provided by Mitsubishi Corporation of Japan, supporting the touch screen for parameter setting, programme editing and real-time monitoring.

● The interface supports multi-language display to meet different user needs and ensure wider adaptability.

● The servo motor and drive system are made by Panasonic brand from Japan and comply with IEC 60034 electrical standard.

● Provides high precision and stability motion control, capable of precisely adjusting the bending angle and position.

● With fast response speed and low noise, the drive system is also equipped with energy efficiency optimisation function to improve productivity.

Our CNC pipe bender is suitable for a wide range of specifications and materials of tubes, can achieve different radii, angles and complex shapes of high-precision bending, whether it is round, square, shaped tube, or stainless steel, carbon steel, aluminium alloy and other materials, can easily cope with, widely to meet the diversified processing needs of automotive, furniture, aerospace, fitness equipment and other industries.

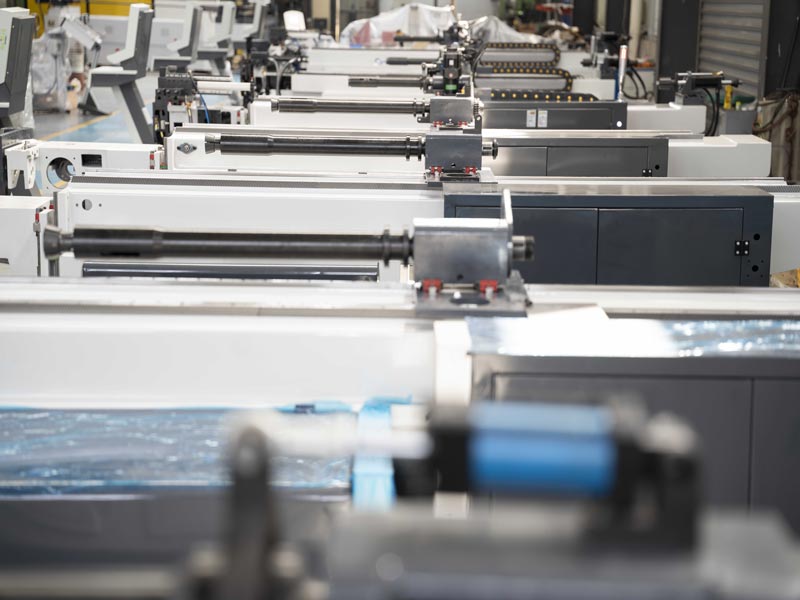

Welcome to our production workshop, which is equipped with advanced CNC machining equipment, fully automatic welding line and efficient assembly line to fully guarantee the precision and quality of each pipe bender. Standardised production processes, clean and orderly working environment and strict quality inspection system is the solid backing for the stability and reliability of our products. Through the real scene display, let you feel our manufacturing strength and professional attitude.