It uses a single-chip NC unit to control the running. The feeding and rotation are positioned by manual, the bending is controlled by a hydraulic cylinder. Suitable to bend simple bend parts or simple multi-plane parts with medium volume.We can use it for bending various materials such as stainless steel, aluminum, copper, carbon steel, etc.

| Parameters | 168NC |

| Control system | NC unit |

| Max bending capability | Φ168x14mm |

| Bending radius | 90~760mm |

| Bending angle | 0~195° |

| Valid mandrel length | 1800mm |

| Bending speed | 65°/sec |

| Bending accuracy | ±0.15° |

| Main motor power | 4Kw |

| System hydraulic pressure | 12MPa |

| Cooling system | water cooling |

| Size | 7100x1900x1700 mm |

● Automatic feeding according to the set programme to ensure stable delivery of tubes.

● Automatic adjustment of tube feeding speed with CNC system for precise control.

● Improve the production efficiency and reduce the instability of manual operation.

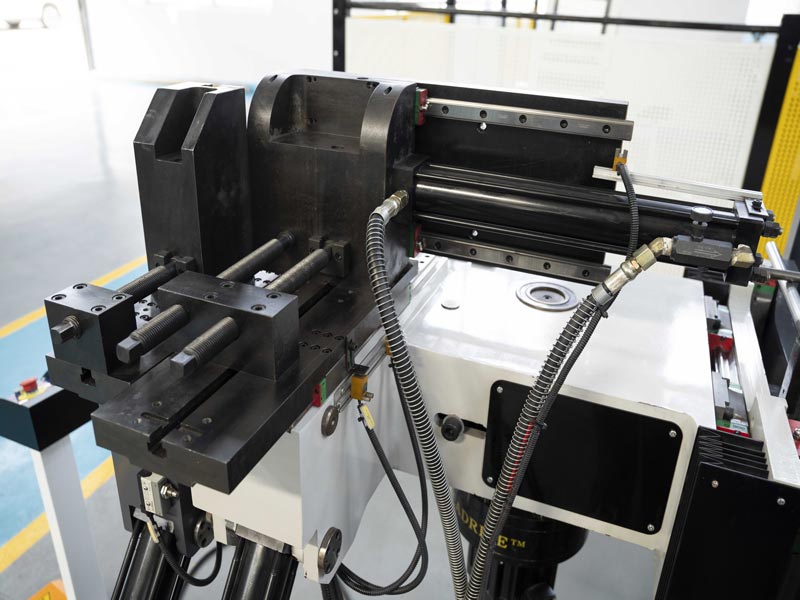

Integrated body, welded with high-strength steel plate, sturdy structure, providing maximum operating space.

● Made of wear-resistant materials for high durability.

● Can be changed quickly according to the pipe specification to ensure bending precision.

● Suitable for all kinds of pipe bending to ensure good bending effect.

● Supplied with fully automatic hydraulic drive for driving the main moving parts of the pipe bender.

● Equipped with high efficiency hydraulic pump and pressure regulator for precise pressure control.

● Ensures stability and consistency in the pipe bending process.

Electrical components adopt Schneider of France, strong performance, good stability, and long service life

Our NC pipe bender is suitable for a wide range of specifications and materials of tubes, can achieve different radii, angles and complex shapes of high-precision bending, whether it is round, square, shaped tube, or stainless steel, carbon steel, aluminium alloy and other materials, can easily cope with, widely to meet the diversified processing needs of automotive, furniture, aerospace, fitness equipment and other industries.

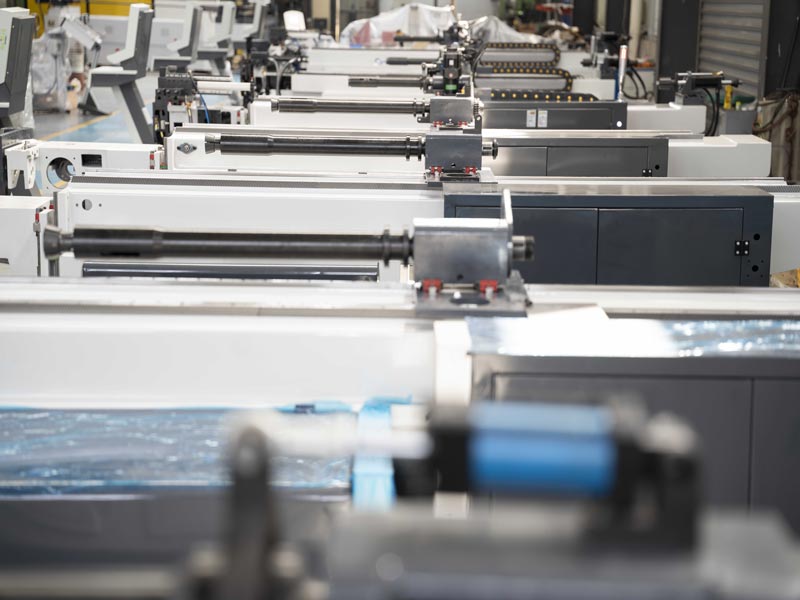

Welcome to our production workshop, which is equipped with advanced CNC machining equipment, fully automatic welding line and efficient assembly line to fully guarantee the precision and quality of each pipe bender. Standardised production processes, clean and orderly working environment and strict quality inspection system is the solid backing for the stability and reliability of our products. Through the real scene display, let you feel our manufacturing strength and professional attitude.