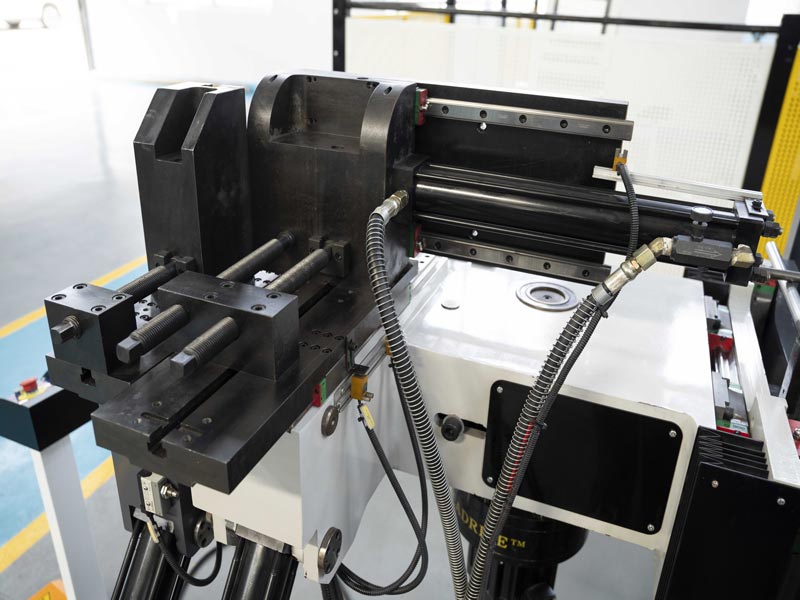

This semi-automatic NC pipe bending machine offers a cost-effective alternative to CNC models, combining manual positioning with hydraulic bending for efficient operation. It is ideal for medium-volume production of simple or moderately complex pipe parts using materials like stainless steel, aluminum, copper, and carbon steel.

| Parameters | SB50NC |

| Control system | NC unit |

| Max bending capability | Φ50×2.5mm |

| Bending radius | 35~220mm |

| Bending angle | 0~195° |

| Valid mandrel length | 2200mm |

| Bending speed | 45°/sec |

| Bending accuracy | ±0.15° |

| Main motor power | 5.5Kw |

| System hydraulic pressure | 12MPa |

| Cooling system | water cooling |

| Size | 3000×1000×1300mm |

Integrated body, welded with high-strength steel plate, sturdy structure, providing maximum operating space.

● Made of wear-resistant materials for high durability.

● Can be changed quickly according to the pipe specification to ensure bending precision.

● Suitable for all kinds of pipe bending to ensure good bending effect.

With manual control, half-cycle control, full automatic control and other functions, overload automatic protection.

The CNC bender's hydraulic system, metal surfaces, motors, bending dies and welded connection parts are all coated with a rust-proof film before shipment to prevent moisture and oxygen from leading to corrosion or rust and to ensure that the equipment stays in good condition during shipment.

NC pipe bender safety protection devices mainly include guards, emergency stop buttons, photoelectric sensors, safety interlocks, two-handed start and alarm systems, etc., designed to effectively prevent operators from contacting dangerous parts, to avoid accidents caused by misuse, to ensure that the equipment in the operation of the process of human-computer separation, real-time monitoring and control of abnormalities, is to protect the safety of production and equipment is the core of the core aspects of stable operation.

Electrical components adopt Schneider of France, strong performance, good stability, and long service life

Our NC pipe bender is suitable for a wide range of specifications and materials of tubes, can achieve different radii, angles and complex shapes of high-precision bending, whether it is round, square, shaped tube, or stainless steel, carbon steel, aluminium alloy and other materials, can easily cope with, widely to meet the diversified processing needs of automotive, furniture, aerospace, fitness equipment and other industries.

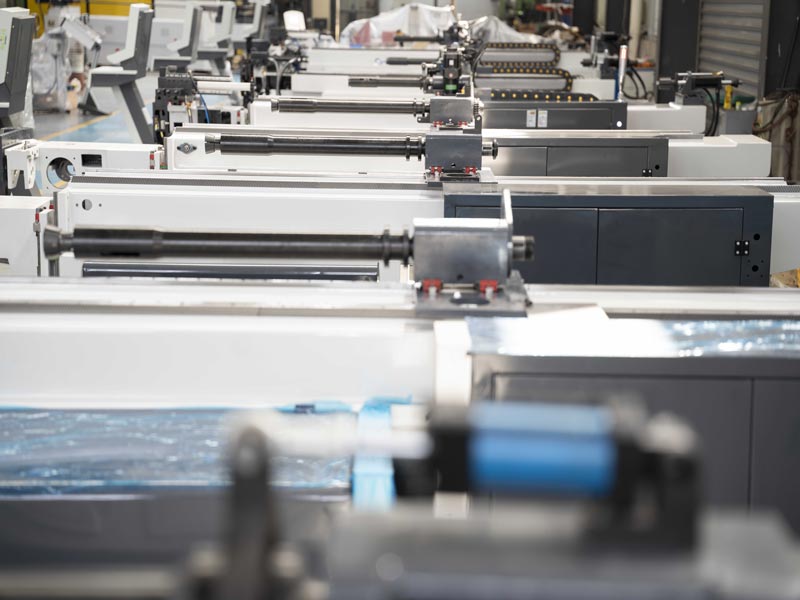

Welcome to our production workshop, which is equipped with advanced CNC machining equipment, fully automatic welding line and efficient assembly line to fully guarantee the precision and quality of each pipe bender. Standardised production processes, clean and orderly working environment and strict quality inspection system is the solid backing for the stability and reliability of our products. Through the real scene display, let you feel our manufacturing strength and professional attitude.