This is a compact, fully automatic CNC pipe bending machine controlled by PLC, featuring automatic feeding, rotating, and bending with servo motors and a hydraulic system. It is especially suitable for processing small-diameter pipes with complex angles and high precision, such as air conditioning tubes and headrests.

| Parameters | 15CNC-2A |

| Max bending capacity ODxWT | Φ15*1.5mm |

| Bending radius | 6-50mm |

| Bending degree | 0-195° |

| Max mandrel length | 900mm |

| Bending speed | 280°/sec |

| Bending accuracy | ±0.15° |

| Feeding speed | 900mm/sec |

| Feeding accuracy | ±0.1mm |

| Rotating speed | 720°/sec |

| Rotating accuracy | ±0.1° |

| Rotating motor power | 200w |

| Feeding motor power | 750w |

| Hydraulic pressure | 4mpa |

| Machine size | 2000*750*1300mm |

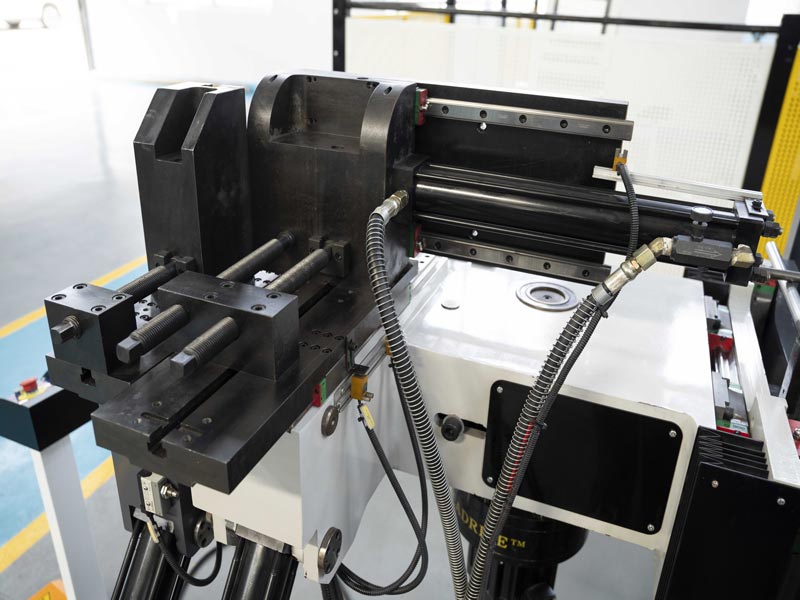

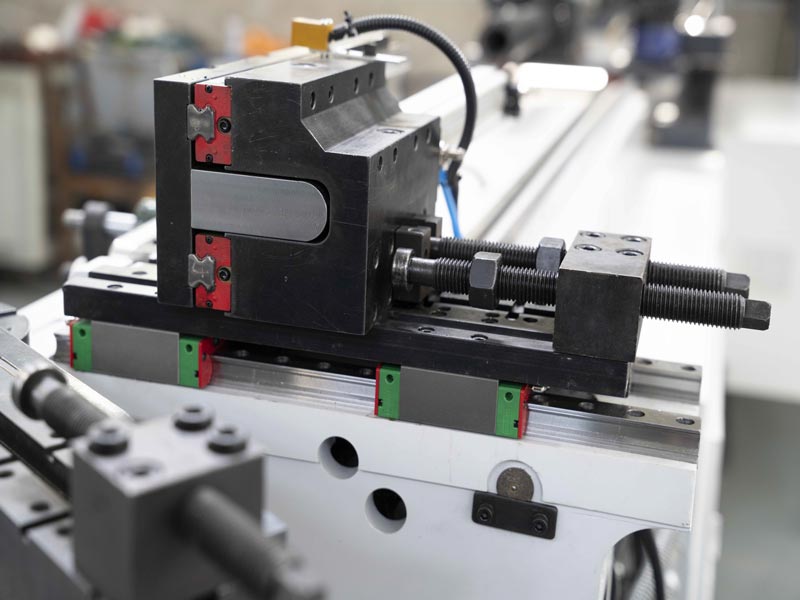

The linear transmission part of the feeding part is composed of imported high-precision ball screw and high-quality wear-resistant linear guide rail, which ensures the accuracy of feeding and the sufficient service life of the machine.

The hydraulic system mainly uses imported brands. The hydraulic circuit has cooling and speed adjustment devices, which are powerful, stable, and durable.

The bending arm adopts imported high-strength silent chain transmission, controlled by oil cylinder, which ensures the power of the bending pipe is abundant.

The CNC bender's hydraulic system, metal surfaces, motors, bending dies and welded connection parts are all coated with a rust-proof film before shipment to prevent moisture and oxygen from leading to corrosion or rust and to ensure that the equipment stays in good condition during shipment.

The hydraulic system mainly uses imported brands. The hydraulic circuit has cooling and speed adjustment devices, which are powerful, stable, and durable.

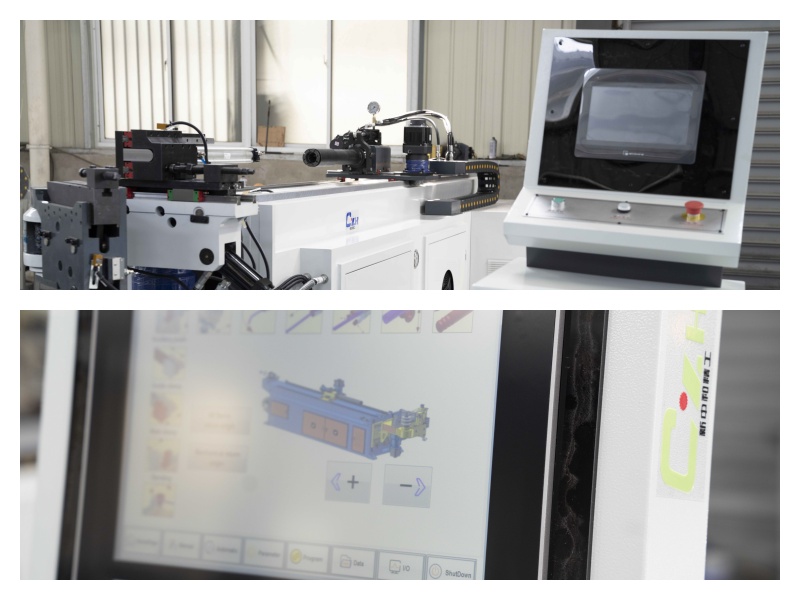

PLC touch screen, human-machine interactive operation, easy to understand. The touch screen can be switched between Chinese and English. Other languages can also be customized.

● The servo motor and drive system are made by Panasonic brand from Japan and comply with IEC 60034 electrical standard.

● Provides high precision and stability motion control, capable of precisely adjusting the bending angle and position.

● With fast response speed and low noise, the drive system is also equipped with energy efficiency optimisation function to improve productivity.

Our CNC pipe bender is suitable for a wide range of specifications and materials of tubes, can achieve different radii, angles and complex shapes of high-precision bending, whether it is round, square, shaped tube, or stainless steel, carbon steel, aluminium alloy and other materials, can easily cope with, widely to meet the diversified processing needs of automotive, furniture, aerospace, fitness equipment and other industries.

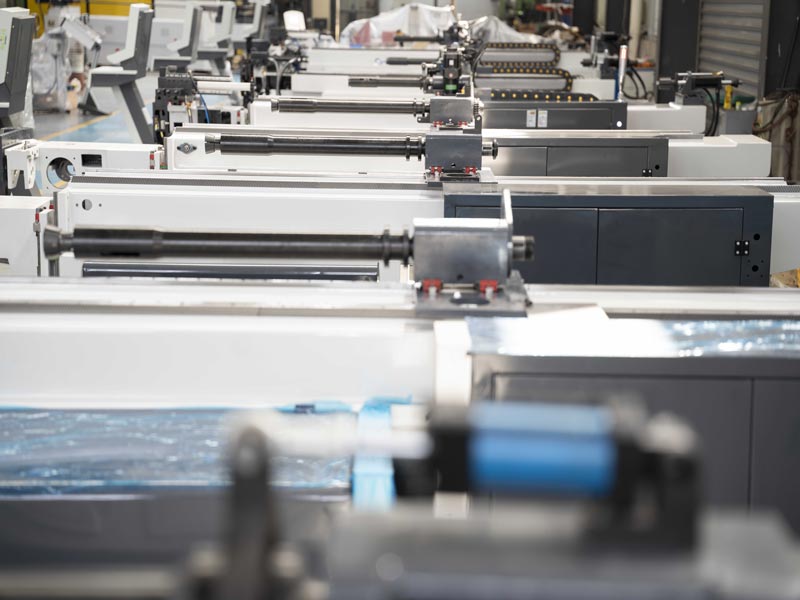

Welcome to our production workshop, which is equipped with advanced CNC machining equipment, fully automatic welding line and efficient assembly line to fully guarantee the precision and quality of each pipe bender. Standardised production processes, clean and orderly working environment and strict quality inspection system is the solid backing for the stability and reliability of our products. Through the real scene display, let you feel our manufacturing strength and professional attitude.